Yes, in about one-third of companies.

In our recent survey, we received 124 responses providing us with some interesting insights on both the causes of this deterioration as well as the reasons why the level of supply chain excellence either stayed the same or got better.

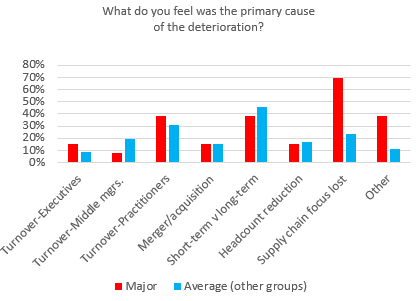

Figure 1:

Actually, two-thirds of companies replying showed deterioration but, as you can see from the chart above, in about half of those the deterioration was not significant.

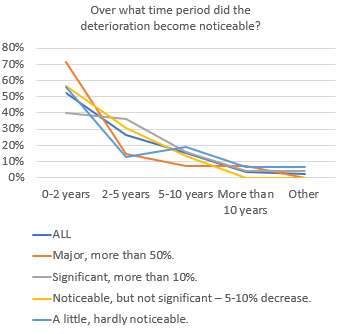

Figure 2:

The half-life for deterioration was fairly short, most happening in less than two years.

Interestingly, the time frame for deterioration in supply chain excellence was essentially the same regardless of whether the companies had experienced a major deterioration or deterioration that was hardly noticeable.

Why would this be?

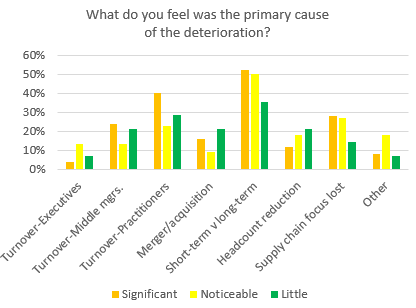

Figure 3:

For the exact wording from the survey, click here.

Among three of the groups, the causes companies listed for deterioration are similar. These three groups are those companies with significant, noticeable, and little deterioration.

The three largest causes were:

– Short-term pressures to fix the problem (but may create future problems).

– Turnover in the people who operate the supply chain day to day.

– Lost focus on the supply chain.

However, this similarity diverges when looking at the group with major deterioration in their supply chain excellence. One difference between the group which experienced major deterioration in supply chain excellence and the others stands out clearly:

Lost focus on the supply chain.

Figure 4:

This is good news. These factors are within most organization’s control. They can be mitigated without making major capital expenditures, and solutions don’t take years to implement.

Notice that executive turnover, middle-management turnover, mergers/acquisitions, and headcount reductions rank lower as reported causes of deterioration in supply chain excellence.

Anecdotally, as we work with companies, we often hear how a new executive, new manager, or merger has ruined things. Yet, that’s not a major source of problems as reported by these companies.

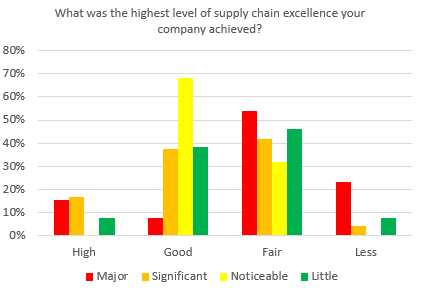

Figure 5:

For the exact wording from the survey, click here.

The responses approximate a bell-shaped curve between the extremes of operating excellent supply chains and not very good.

This is not surprising since most things work this way.

It’s worth noticing something in both Figure 4 and Figure 5 about the companies who reported major deterioration in supply chain excellence. Figure 4 shows these companies lost focus more than the others, and Figure 5 shows significantly fewer of this group had achieved “good but not great” levels of supply chain excellence.

The companies who did not have as well-run a supply chain as the others had the most significant deterioration, and that deterioration was mostly from losing focus on the supply chain.

One view of this, and we don’t have the data to either support or refute it, is that these companies may never have viewed their supply chain as a valuable element in the competitive equation.

While this must be disheartening to the people in these companies, the good news is that, again, it can be fixed without huge cost or a multi-year project.

It’s also insightful to look at companies where the level of supply chain excellence stayed the same or got better.

These respondents provided open-ended answers to why they were able to maintain or improve their level of supply chain excellence.

We have taken the liberty to categorize these into the following groupings (click here to see the actual text from these respondents and our categorization).

Figure 6:

In this chart:

– Improvement means an attitude which expects improvement, desires to be better, not satisfied with the status quo.

– People means existing people who are good at their jobs, new people, investments in people like education, training, communities, etc.

– Mindset means being a pioneer, passionate about success, desire for excellence.

Not surprisingly, focus appears as one of the primary reasons for supply chain excellence which did not deteriorate – consistent with Figure 4 where loss of focus was dominant in the group with major deterioration in supply chain excellence.

An attitude of improvement (desire to be better, not satisfied with status quo) is by far the major factor in maintaining or improving supply chain excellence.

Again, good news for the reasons mentioned earlier: no large capital expenditure, under the company’s control, and doesn’t take years to implement.

Quick Summary

Taken as a whole, this survey supports one of Tom Peters’ frequent dictums, “Hard is soft, soft is hard.”

In this context, large hard-dollar benefits come from maintaining supply chain excellence.

Soft principles like “doing it right,” retaining good people, maintaining focus, and striving to do better appear to be major factors in avoiding supply chain deterioration and maintaining these benefits.

These soft principles are hard to do consistently and visibly.

If you’re interested in some additional observations on this, please click on the appropriate link below.

I’m an executive, how do I fix this and/or prevent deterioration in my supply chain? Click here.

I’m a practioner, how do I help my company recover from deterioration and/or prevent it from happening? Click here.